When it comes to efficient shiploader for port operations, selecting the right shiploader can make all the difference. With various types of shiploaders available, it’s essential to choose one that aligns with your specific port needs — ensuring faster loading times, increased capacity, and minimized downtime. In this guide, we’ll walk you through the key factors to consider when selecting the best shiploader for port operations.

Your favorites

Your quotation

Best Shiploader for Port Operations: How to Choose

Challenges in Choosing the Right Shiploader for Port Operations

Choosing a shiploader isn’t always straightforward. Here are some common challenges buyers face when selecting equipment for their port:

Capacity vs. Need

Port managers often struggle with finding a shiploader that balances capacity with their specific throughput requirements.

Cost Considerations

With a wide range of prices, understanding the total cost of ownership—including maintenance and operation costs—is crucial.

Logistical Concerns

Ports that deal with heavy cargo need a shiploader that can withstand high volumes and harsh conditions.

Adaptability

Many ports have unique loading needs, meaning off-the-shelf solutions may not work without modifications or adjustments.

Key Factors to Select the Best Shiploader for Efficient Port Operations

When selecting the right shiploader for port operations, consider the following factors:

1. Loading Capacity & Speed of a Port Shiploader

Choose a shiploader that can match the volume of cargo your port handles. For instance, if your port exports bulk grain, you’ll want a high-capacity loader to handle large amounts of cargo quickly.

2. Shiploader Durability for Harsh Port Environments

Will the shiploader be exposed to extreme weather conditions, salty water, or other harsh environments? Be sure to choose a model that’s durable and designed for long-lasting performance under tough conditions.

3. Space and Flexibility in Shiploader Placement

Measure your port space and determine how much room you have for a loader. If you have limited space, consider a compact shiploader or a model with adjustable parts to fit your needs.

4. Maintenance and Support for Long-Term Shiploader Use

Evaluate the long-term maintenance costs and availability of parts. A reliable brand like Van Trier can provide ongoing support to ensure your equipment continues to perform well over time.

Best Shiploader Options Based on Cargo Material Type

Different materials have different densities, behaviors, and flow characteristics — and your shiploader must be suited for the material you plan to transport. Selecting the wrong configuration can lead to reduced performance, faster wear and tear, or even damage to your equipment.

Here are examples of how material type influences shiploader selection:

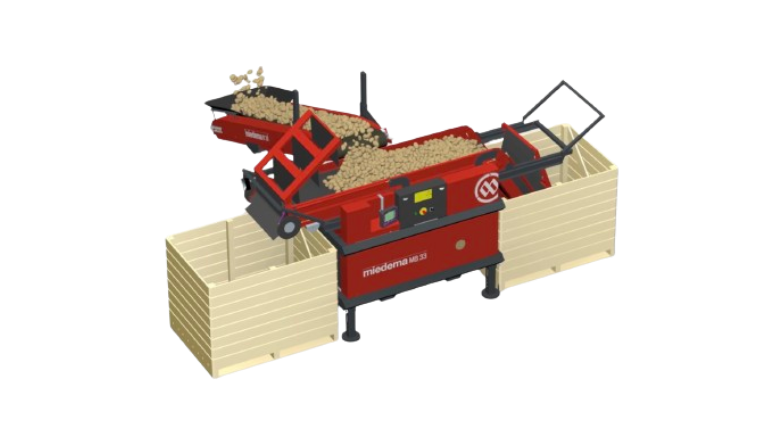

🌾 Grain Handling Shiploaders (e.g., wheat, corn, soybeans): Light and Fast

Light and free-flowing. A lighter shiploader with standard motors works well. Consider dust-control systems for hygiene and reduced loss.

🏖️ Heavy-Duty Shiploaders for Sand and Gravel

Dense and abrasive. Requires a reinforced frame, stronger motor, and heavy-duty components to handle the load and resist wear.

🧂 Corrosion-Resistant Shiploaders for Salt and Fertilizers

Corrosive. Needs corrosion-resistant materials, enclosed belts, and special coatings to protect components from damage.

🌿 Shiploader Solutions for Biomass and Wood Chips

Bulky but lightweight. Ideal for high-capacity shiploaders with wide belts and adjustable booms to handle uneven or inconsistent material flow.

⚙️ Industrial Shiploaders for Ore, Coal, and Clinker

Extremely heavy. Demands industrial-grade loaders with high torque motors, wear-resistant parts, and integrated dust suppression systems.

✅ Pro Tip: Always match your shiploader specs to the bulk density and material type. Our team at Van Trier can help assess and recommend the best configuration.

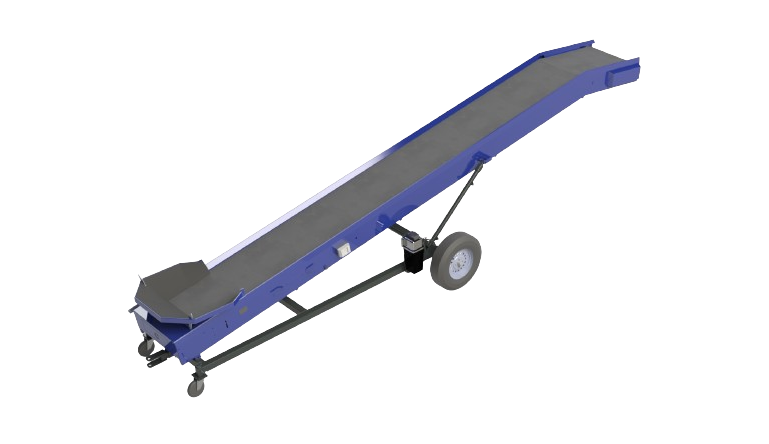

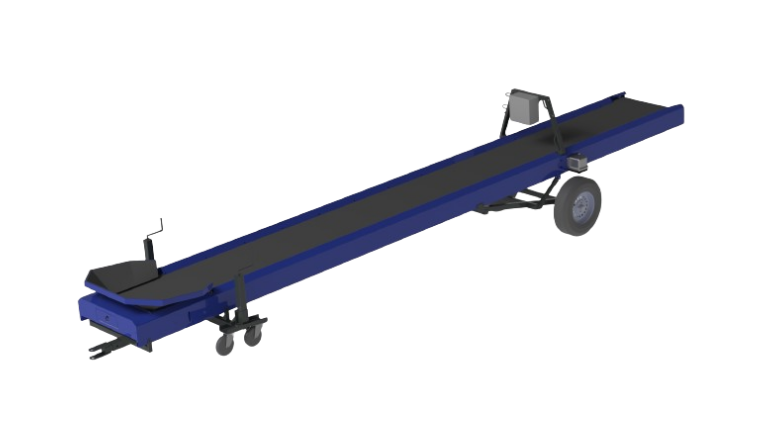

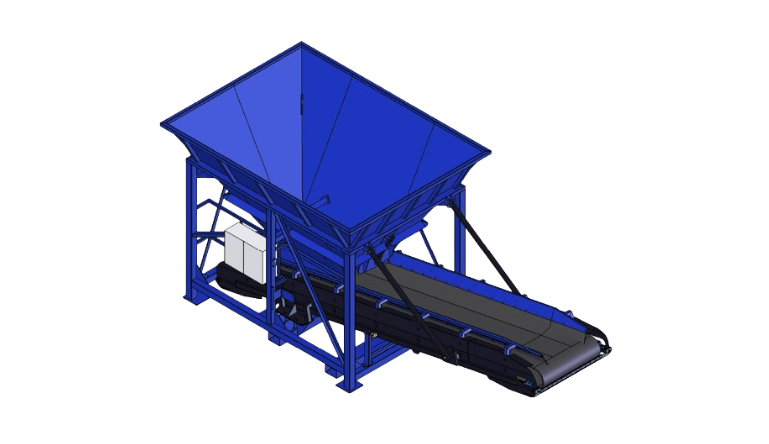

Case Study: Breston Z25-100XW Shiploader Used in Port Operations

The Breston Z25-100XW Shiploader is an excellent example of a machine designed for high-efficiency port operations. One of our clients, a large grain exporter in Ukraine, recently invested in this model. They needed a shiploader capable of handling large volumes of grain, while also fitting in a tight space. The Z25-100XW was the perfect solution.

-

High capacity: Breston Z25-100XW Shiploader can load large amounts of cargo efficiently.

-

Adjustable boom: Flexible loading system suited for varying port environments.

-

Reduced loading time: Increased throughput, cutting loading time per ship by over 30%.

Its easy-to-maintain design also meant they spent less time on repairs and more time on productive work.

Contact Van Trier for the Right Shiploader for Your Port

Choosing the right shiploader for port operations can significantly impact your efficiency, safety, and long-term cost savings. At Van Trier, we specialize in helping ports find the perfect solution — from grain loaders to heavy-duty systems for bulk materials.

📞 Contact Us Today:

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus

Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus Craftsmanship, innovation and customer focus